Just share one beautiful buffalo horn eyewear model.

Hot style, looks like Moscot shape, purely natural buffalo horn.

This model is quite classic buffalo horn eyewear. Someone like it?

Just share one beautiful buffalo horn eyewear model.

Hot style, looks like Moscot shape, purely natural buffalo horn.

This model is quite classic buffalo horn eyewear. Someone like it?

Titanium eyewear is in fashion now, because titanium eyewear has many excellent properties

1, light weight, about 40% lighter than stainless steel eyewear and nickel silver eyewear.

2, High hardness, about twice hardness to other metal eyewear such as stainless steel eyewear and four times hardness to ordinary nickel silver eyewear, In the cryogenic world, titanium eyewear has become more hard, and have the properties of superconductors, the stainless steel eyewear becomes weak and incompetent.

3, Corrosion-resistant, won’t rust. Titanium eyewear won’t rust soak in the sea water for 5 years, stainless steel eyewear must corrosion in sea water.

4, Touches and feeling good, Titanium eyewear warm and silky to the touching, other metal eyewear has cold metallic feeling.

5, No skin allergy, titanium eyewear does not produce allergic reactions to humans skins, also titanium is used in human body, such as artificial teeth, artificial bones.

Titanium eyewear because of its light weight, corrosion resistance, and non-allergic quality features has becomes a new trend. But compared to other metal eyewear, acetate eyewear, titanium eyewear price is much higher.

Why the Titanium eyewear is expensive?

One reason is the current titanium raw material costs are too high

The other reason is the production of titanium metal frames is very complex

The production of titanium eyewear requires special processing equipment, special welding technology and electroplating technology, many high difficult and different processes with normal metal eyewear, so it with high production costs.

With the emergence of new titanium eyewear production equipment, as well as the improvement of industry production and processing technology, titanium eyewear will become lower prices to a wider people.

Metal eyewear is completed by using the welding machine, with about 40% to 69% the purity of silver brazing wire welding. Welding group main process: welding rim lock→ open rim lock→ welding metal bridge →welding cross bridge→ welding nose arm→ welding hinge→ welding spring hinge box→ welding frame, What can we do if any part of metal eyewear was broken?

During the metal eyewear producing process, the metal eyewear was welded in the mould. The mould main function is to ensure accurate position of welding on metal frame. The welding machine through instant high temperature to melt metal and put pressure on the two metal parts together and so it does not harm the original shape.

Generally, weld broken metal eyewear almost belonged to damaged, It is not to say cannot rework the welding, but it will completely destroyed plating layer when welding, it is hard to weld in a daily environment, even if reluctantly welding, the plating was damaged and the metal frame will lost the original shape.

In fact, metal eyewear plating color fall off is the problem of plating issue, it has nothing to do with metal eyewear. Usually the metal eyewear is required to be plated finished. Here we introduce several plating process for metal eyewear and their advantages and disadvantages.

Electrophoresis plating, commonly known as “water-plating”, it refers of coating mirror surface on metal eyewear by electrolytic method, more commonly used in normal alloy metal eyewear. To take example, stainless metal eyewear, nickel silver metal eyewear etc..

Advantages: low cost, and rich colors

Disadvantages: Very low coating adhesion, gold, silver, gun generally available for about a year; other colors generally can occur color fall off in 3-6 months.

Most Chinese eyewear supplier applies water-plating method coating metal eyewear.

Heavy gold electroplate–divided into “multi-layer texture coating method” and “the multilayer plating method” of two kinds. These two kinds of galvanization technological requirement is a natural metal color, thus the frame color is a single adopting of such processing, basically gold, silver major color.

The feature is coated with a thick 3.5UM gold or silver, generally available for about many years, no skin irritation and discomfort complaints.

IP vacuum ion plating: heat frame surface to form negative ions, free in a vacuum furnace, combined with the pigment particles through current electrodes to the lead adsorption on the surface of frame plating layer is formed.

Advantage: Eco-friendly, strong electroplated coatings adhesion, generally available for about many years without color falling off.

Weaknesses: color is gloomy, plating is not bright.

Multi-coated divided into spraying and paint two types.

A, spraying process: used for many students metal eyewear outer coating and covering.

Advantages: rich colors, bright

Disadvantage: prone to falling off and fading.

B, baking varnish technology: Used for fashion frames;

Advantages: coating thick, colorful and bright

Disadvantages: easy to scratch, color fall off.

There are various metal eyewear plating method, quality plating refers to electroplating equipment, materials, technology and other related factors, compared to other plating method, vacuum ion plating process is more complex, technical requirements for equipment are higher, so it is not easy to color falling off, the plating cost more expensive.

Usually, metal eyewear material ranges are nickel silver, stainless steel, titanium etc… These materials processed through precision processing, e-plated with gold, silver, or popular painting colors finish. Metal eyewear is sturdy and durable; it has smooth surface and good appearance, light weight. Following is a brief introduction about our metal eyewear producing process:

1. After we receive customer’s order, we will study carefully as per customer’s specific requirements; we will work and confirm with customers every detail in order to ensure that the products meet customer’s specific requirements. During the producing processes, the production order will be arranged to different departments such as design department, material procurement department, accessories department, assemble department, e-plating and painting department, assembling and shipping department.

2. Samples production. We can make the technical drawings as per customer’s specific requirement and physical samples. After the drawing approved well, samples production will be started, we will ship the samples for our customer approval. Final confirmation of the sample is the basis of our products basis.

3. Material preparing. Our materials procurement department will book material according to customers orders needs, the material includes eye wire, bridge metal and end piece and other accessories, temples tips material etc. Metals generally have nickel silver, stainless steel, titanium etc, in order to ensure the quality; most of metal materials we used are high quality which imported from foreign.

4. Accessories producing, After material reach to us, we will process oil pressed or wire cutting the material or semi-finished products, then the accessories will go through bending, cutting, welding, polishing, tumbling, shinny, etc.

5. Welding group main process: welding rim lock→ open rim lock→ welding metal bridge →welding cross bridge→ welding nose arm→ welding hinge→ welding spring hinge box→ welding frame

6. Acetate parts group process (including temples tips, plastic temples): acetate cutting→ shooting metal core→ cut temple→ temple decorating →handiwork→ bend temples→ tumbling → polishing →QC, final process is for frame assembling.

7. Lens cutting. Firstly making eye mold based on CAD drawing, and then fix eye mold on cutting machine to cut lenses.

Assemble process. According to the orders assembling group assemble for the front, temples/temples tips, lenses. So that a complete metal eyewear are finished.

8. Final inspection. After the assembly is completed, if metal eyewear has attached acetate temple tips, it will process final polishing and shinny, and then clean the frame and process final inspect. All products must get through final inspection before shipment.

Finally, according to the requirements of the customers, we ship the goods through express (usually we use FedEx, DHL, or UPS) or by air to transport the goods to the customer’s hands, we’ll do the tracking and trance for the goods, once we find the shipping problem, we will act promptly to handle the problem. After customer receive the products, customer feedback with any questions, our related person will seriously study and then make a proper processing until customer satisfied.

Our factory most competitive products are metal eyewear, acetate eyewear and buffalo horn eyewear.

For buffalo horn eyewear wearers, the most difficult problem is probably the buffalo horn eyewear out of shape.

It is a troublesome problem for the wearers, it will not only affect the users comfortable wearing, but also cause wearers feel fatigue, and headaches. If users wear such frame, in some cases, even endanger to the health of the wearers eyes.

Why buffalo horn eyewear out of shape?

Formerly, buffalo horn is a purely natural products and horn original texture and shape is curved, so horn raw materials have features of memory functions.

From our industry experience, other buffalo horn eyewear suppliers products is easily out of shape, some suppliers products won’t out of shape. How come it is?

Since a piece of horn material width is 170mmx60mm, during produce buffalo horn arms. In order to save horn material. Other buffalo horn eyewear suppliers engrave straight arms. In this method, they are able to cut out 2 pairs of arms, thus saving some production cost and make more profits.

However, this method was likely to cause products out of shape. Because these straight buffalo horn arms need bending procedure, for a few time, horn original texture and shape must bounce back into the original straight, eventually leading to the wearer’s buffalo horn eyewear out of shape.

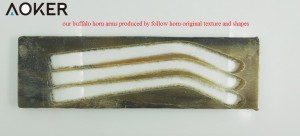

In order to prevent buffalo horn eyewear out of shape because of memory functions, during engrave buffalo horn arms, our factory totally follows horn original texture and shapes. In this method, buffalo horn arm is a naturally curvature. No need bend-shape by hand in later procedures. These natural bending arms are not easy out of shape compared with straight arms. It is also not easily out of shape in wearer’s hand.

Actually, following horn original texture and shapes spends more horn material. If arms width relative big. Base on measurement 170mmx60mm horn raw material. It can only produce 1 pair of arms. For straight arms, it can produce 2 pair of arms. Our costs are increased by one half.

As a professional buffalo horn eyewear supplier, in order to peruse a high end quality buffalo horn eyewear product. We guarantee that all our buffalo horn arms produced by follow horn original texture and shapes.