For many eyewear users, the convenience of having one pair of glasses that can adapt to changing light conditions is highly appealing. Enter photochromic lenses, also known as adaptive or transition lenses. These lenses automatically adjust their tint based on the amount of sunlight, offering a seamless transition between indoor and outdoor environments. In this article, we will explore the science behind photochromic lenses and how they revolutionize the world of sunglasses.

The Science of Photochromic Lenses

At the heart of photochromic lenses lies a fascinating chemical reaction. These lenses contain millions of microcrystals made of organic compounds, such as silver chloride or silver halide, which are embedded within the lens material. When exposed to ultraviolet (UV) light from the sun, these compounds undergo a chemical reaction that causes them to change their molecular structure, absorbing more light and darkening the lens.

Adapting to Light Conditions

One of the most impressive features of photochromic lenses is their ability to adapt to different light conditions. When you step outside on a sunny day, the UV light triggers the chemical reaction in the microcrystals, causing them to darken and transform your eyeglasses into sunglasses. This process can take anywhere from 30 seconds to a few minutes, depending on the intensity of the sunlight and the specific lens technology.

Conversely, when you go back indoors or enter a shaded area with less UV light, the microcrystals revert to their original molecular structure, allowing more light to pass through and lightening the lens tint. This adaptability ensures that your sunglasses always provide the optimal level of protection and comfort, no matter the lighting conditions.

Enhanced Eye Protection

In addition to their adaptive properties, photochromic lenses also offer excellent protection against harmful UV rays. Most photochromic lenses block 100% of UVA and UVB radiation, shielding your eyes from the sun’s damaging rays and reducing the risk of long-term eye health issues, such as cataracts and macular degeneration.

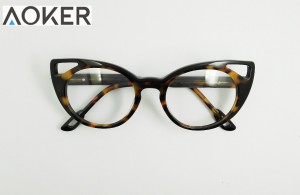

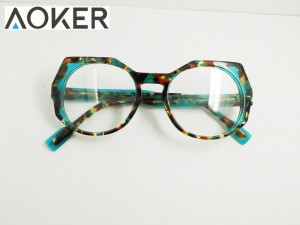

Customization and Style Options

Photochromic lenses come in a variety of customization and style options, making them suitable for a wide range of eyewear users. They can be combined with various lens materials, such as polycarbonate or high-index lenses, and can even be integrated into prescription sunglasses. Furthermore, some photochromic lenses are available in different tint colors, such as brown or grey, allowing you to choose a style that suits your personal preference.

The Future of Sunglasses

As technology continues to advance, so does the world of photochromic lenses. Innovations in lens materials and coatings have led to faster transition times and improved performance in various light conditions. Some of the latest advancements even allow photochromic lenses to activate behind car windshields, which typically block most UV light, making them more convenient for drivers.

In conclusion, photochromic lenses provide a unique and practical solution for eyewear users who want the convenience of sunglasses that automatically adapt to changing light conditions. By understanding the science behind these lenses and their various features, you can make an informed decision about whether photochromic lenses are the right choice for your eyewear needs. Next time you pick up a pair of sunglasses, consider the benefits of photochromic lenses and experience the seamless transition between indoor and outdoor environments for yourself.

As a processional eyewear supplier, we are specialize in photochromic acetate eyewear and metal eyewear.